Have you ever wondered about the difference between a mitre saw and a cut off saw? Well, look no further, because this article will provide you with the answers you’ve been seeking. Whether you’re a DIY enthusiast or a professional in the construction industry, understanding the variances between these two power tools is essential for making the right choice for your projects. In this article, we’ll explore the features, functions, and applications of both the mitre saw and the cut off saw, so you can confidently select the tool that best suits your needs.

Definition of Mitre Saw

A mitre saw, also known as a chop saw or a drop saw, is a power tool used to make accurate crosscuts and mitre cuts in wood, plastic, or metal. It consists of a motorized circular saw blade mounted on a swing arm that can be adjusted to different angles. The key feature of a mitre saw is its ability to pivot and tilt, allowing users to make precise cuts at various angles and bevels.

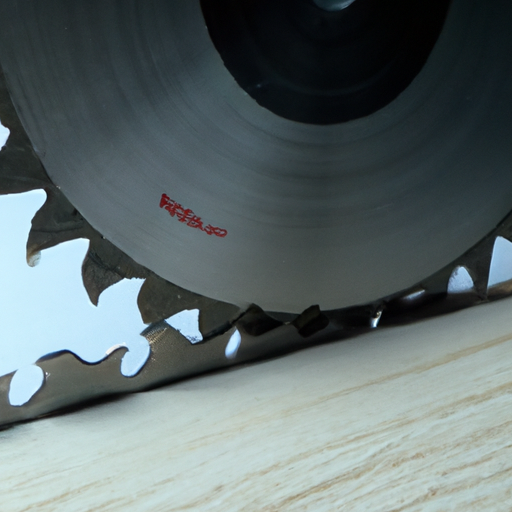

Definition of Cut Off Saw

A cut off saw, also referred to as a chop saw or a cutoff saw, is a powerful cutting tool specifically designed for making straight cuts through metal, concrete, or other tough materials. Unlike a mitre saw, a cut off saw operates in a fixed position and does not have the ability to pivot or tilt. It is typically equipped with a reinforced abrasive or diamond-cutting blade that can swiftly slice through rigid materials.

Design and Structure

Mitre Saw Design

Mitre saws are built with a sturdy and compact design, primarily consisting of a base, a motor housing, a swing arm assembly, and a rotating table. The base serves as a stable platform, while the motor housing holds the power source that drives the saw blade. The swing arm assembly allows for the up-and-down movement of the blade, while the rotating table enables the operator to make precise angle cuts. Mitre saws often feature a safety guard system that protects the user from accidental contact with the blade during operation.

Cut Off Saw Design

Cut off saws are designed to withstand the demanding nature of cutting through tough materials. They typically come with a robust cast iron base, providing stability and reducing vibrations. The motor housing of a cut off saw is built to withstand high torque and heat generated during cutting. The blade guard, made of durable materials, shields the operator from sparks and debris. Additionally, most cut off saws have an adjustable fence to ensure accurate and straight cuts.

Blade Type

The choice of blade type depends on the intended use and the material being cut. Mitre saws usually come with a circular saw blade that has fine teeth, designed for cutting wood or plastic. These blades are engineered to provide clean and precise cuts. On the other hand, cut off saws often use abrasive or diamond blades specifically designed for cutting through tough materials like metal or concrete. These blades have a coarse texture and are capable of withstanding extreme heat and pressure.

Blade Size

Both mitre saws and cut off saws are available in various blade sizes, ranging from as small as 7 inches to as large as 12 inches or more. The blade size you choose depends on the cutting capacity required for your specific tasks. Smaller blades are suitable for cutting thinner materials, while larger blades offer greater cutting depth and are ideal for thicker materials. It is important to note that the blade size also affects the overall size and weight of the saw, so consider the portability factor when choosing a blade size.

Cutting Capacity

Mitre Saw Cutting Capacity

Mitre saws are designed to handle a wide range of cutting capacities. They typically have a maximum crosscutting capacity, which refers to the width of the material that can be cut from left to right. The average mitre saw can handle crosscuts ranging from 8 to 12 inches or more. Additionally, mitre saws can also perform mitre cuts and bevel cuts, allowing you to create angled and tilted cuts for various woodworking projects.

Cut Off Saw Cutting Capacity

Cut off saws are primarily used for making straight cuts through tough materials. Their cutting capacity is determined by the size and power of the saw. Cut off saws with larger blades typically have a greater cutting depth, allowing them to slice through thicker materials. Some heavy-duty cut off saws can cut through metal pipes or concrete blocks with ease, thanks to their high power and cutting capacity.

Accuracy and Precision

Mitre Saw Accuracy and Precision

Mitre saws are renowned for their exceptional accuracy and precision. The ability to pivot and tilt the blade allows users to make precise angled cuts with ease. Most mitre saws come with angle presets, enabling quick and accurate adjustments. Furthermore, mitre saws often feature laser guides or LED lights that project a visible line onto the material, aiding in precise alignment and ensuring accurate cuts. These features contribute to the overall accuracy and precision of the mitre saw.

Cut Off Saw Accuracy and Precision

Cut off saws are primarily designed for straight cuts, and they excel in delivering accurate and precise results. Their fixed position and sturdy structure minimize any potential blade wobble, ensuring that the cuts remain straight and true. Many cut off saws also offer adjustable cutting angles, allowing users to make bevel cuts while maintaining accuracy. To further enhance the precision, some models have integrated adjustable stops and guides to assist in achieving consistent and accurate cuts.

Applications

Mitre saws are widely used in woodworking projects, such as building furniture, installing trim or molding, creating frames, and constructing cabinets. Their ability to make angled and beveled cuts makes them versatile for tasks that require precise measurements and angles. On the other hand, cut off saws are commonly employed in construction, metalworking, and masonry industries. They are ideal for cutting metal pipes, rebar, concrete blocks, and other rigid materials that require precise and clean cuts.

Portability

When it comes to portability, mitre saws and cut off saws differ in their designs. Mitre saws are generally more portable due to their compact structure and lightweight materials. They are often equipped with carry handles and may have additional features like foldable legs for easy transportation. Conversely, cut off saws tend to be heavier and bulkier due to their robust construction, making them less portable. However, some cut off saws come with built-in wheels or have ergonomic designs to facilitate mobility within work environments.

Safety Features

Both mitre saws and cut off saws prioritize safety and include various features to protect users from potential hazards. Mitre saws typically come with blade guards that cover the exposed portion of the rotating blade, preventing accidental contact. Additionally, mitre saws often incorporate safety switches and electronic braking systems, automatically stopping the blade when released. Cut off saws also feature blade guards, along with safety locks and emergency stop buttons to ensure safe operation. It is crucial to follow the manufacturer’s instructions and wear appropriate safety gear when using either type of saw.

In conclusion, mitre saws and cut off saws are valuable tools in their respective applications. Mitre saws excel in woodworking projects, providing accurate angled and beveled cuts, while cut off saws are ideal for making straight cuts in tough materials like metal and concrete. Understanding the differences in their design, blade types, cutting capacities, and safety features will assist you in selecting the right tool for your specific needs. Always prioritize safety and follow proper usage guidelines to ensure efficient and secure operation of these power tools.