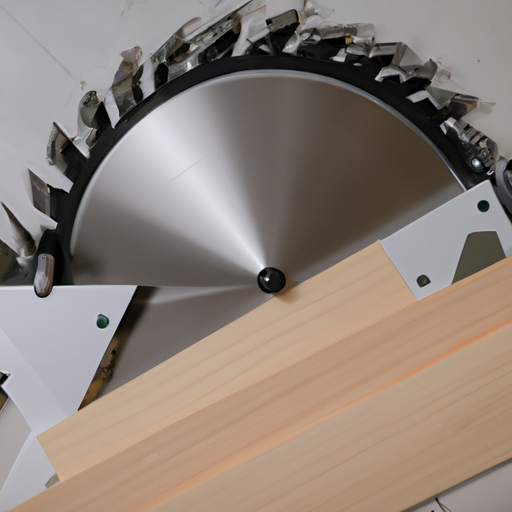

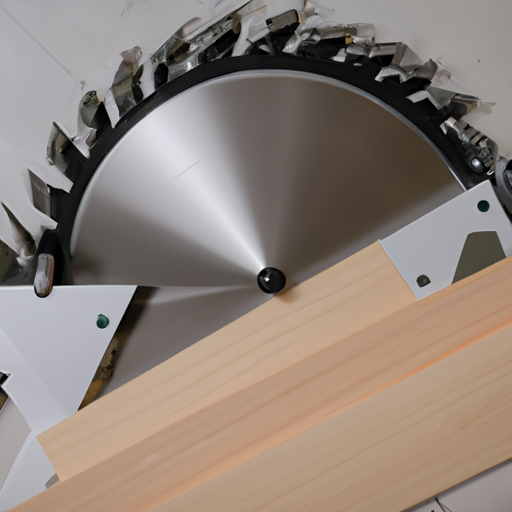

So you’ve decided to take on a laminate flooring project, but you’re struggling to find the perfect tool to make those precise cuts. Look no further! Introducing the “Best Miter Saw Blade For Laminate Flooring”. This exceptional product is specifically designed to deliver clean and accurate cuts on laminate flooring, giving your project a professional finish. With its high-quality construction and superior cutting performance, this miter saw blade is an absolute game-changer for any DIY enthusiast or professional contractor. Say goodbye to uneven edges and say hello to flawless results with the Best Miter Saw Blade For Laminate Flooring.

Choosing the Right Miter Saw Blade

When it comes to laminate flooring, choosing the right miter saw blade is crucial for achieving clean and precise cuts. With so many options available on the market, it can be overwhelming to determine which blade is best suited for your specific needs. This article will guide you through the factors to consider when selecting a miter saw blade for laminate flooring, as well as provide recommendations for top brands and offer maintenance tips to ensure longevity and optimal performance.

Understanding the Material

Before diving into the features and types of miter saw blades, it’s important to have a basic understanding of the material you’ll be working with. Laminate flooring is composed of layers of compressed wood particles, topped with a decorative layer and finished with a protective coating. The key to cutting laminate flooring accurately lies in using a blade that can cleanly and efficiently slice through these layers without causing chipping or splintering.

Considering the Tooth Count

One of the essential factors to consider when choosing a miter saw blade for laminate flooring is the tooth count. The tooth count refers to the number of teeth present on the blade. Generally, a higher tooth count indicates a smoother cut, while a lower tooth count is more suited for quick and rough cuts. For laminate flooring, a miter saw blade with a higher tooth count, such as 80 teeth or more, is recommended to achieve clean and precise cuts with minimal chipping.

Opting for Carbide Teeth

Carbide is a popular material used for miter saw blade teeth due to its exceptional durability and hardness. Carbide teeth are capable of maintaining their sharpness for a longer period compared to traditional steel teeth, making them ideal for cutting through laminate flooring. When choosing a miter saw blade for laminate flooring, opt for one with carbide teeth to ensure longevity and consistently accurate cuts.

Selecting the Right Blade Diameter

Another crucial aspect to consider when choosing a miter saw blade for laminate flooring is the blade diameter. The blade diameter determines the size of the cuts you can make with your miter saw. For laminate flooring, a blade diameter between 10 inches and 12 inches is recommended. This size enables you to make precise and clean cuts, regardless of the width or length of your laminate boards.

Blade Types for Laminate Flooring

Now that you have a good understanding of the factors to consider when choosing a miter saw blade, let’s explore the different types of blades specifically designed for laminate flooring.

Crosscut Blade

A crosscut blade is designed to make smooth and clean cuts across the grain of the laminate flooring. This type of blade typically has a higher tooth count and a beveled edge to ensure precise and chip-free cuts. Crosscut blades are an excellent choice for laminate flooring installation projects that require accurate and finished edges.

Rip Blade

On the other hand, a rip blade is primarily used for cutting laminate flooring along the grain. This type of blade has a lower tooth count and larger gullets, which enable it to remove material more efficiently during the cutting process. Rip blades are ideal for making long, straight cuts when fitting laminate flooring pieces together or resizing them to fit a specific area.

Combination Blade

If you’re looking for versatility and the ability to perform both crosscuts and rip cuts, a combination blade is an excellent option. Combination blades are designed with a combination of teeth that enable them to handle various cutting tasks, including laminate flooring. These blades strike a balance between the high tooth count of crosscut blades and the lower tooth count of rip blades, making them a versatile choice for laminate flooring projects that involve both types of cuts.

Features to Look for in a Miter Saw Blade

To further enhance your cutting experience and achieve the best results, there are a few key features to look for in a miter saw blade for laminate flooring.

Anti-Vibration Design

An anti-vibration design helps reduce the amount of vibration produced by the miter saw blade during operation. Excessive vibration can impact the accuracy of your cuts and potentially affect the lifespan of the blade. Look for a miter saw blade with anti-vibration features to ensure smooth and precise cuts without compromising the integrity of the blade or your work surface.

Thin Kerf

The term “kerf” refers to the width of the cut made by the saw blade. A thin kerf blade is preferred for cutting laminate flooring as it minimizes the amount of material removed while reducing the strain on the miter saw motor. Additionally, thinner kerf blades produce less waste and require less power to operate, resulting in smoother and more efficient cuts.

Coating for Reduced Friction

Some miter saw blades are coated with special friction-reducing coatings. These coatings help reduce the amount of heat and friction generated during the cutting process, which can lead to smoother cuts and prolong the blade’s lifespan. Look for blades with coatings such as Teflon or titanium nitride for improved performance and enhanced durability.

Noise Reduction

Miter saws can be noisy, especially when using them for extended periods. To reduce noise levels and make your cutting experience more comfortable, consider choosing a miter saw blade with built-in noise reduction features. These blades are specially designed to dampen vibrations and reduce noise, making them an excellent choice for those who value a quieter working environment.

Precision and Clean Cuts

While not a specific feature, it’s essential to select a miter saw blade that consistently delivers precise and clean cuts. Look for blades with high-quality construction and reputation for accuracy. Reading reviews and seeking recommendations from professionals or experienced users can help you identify blades that consistently meet or exceed expectations.

Top Brands and Recommendations

Now that you have a good understanding of the factors to consider and the features to look for in a miter saw blade for laminate flooring, here are some top brands and specific blade recommendations to help you make your decision:

Freud D12100X 100T Diablo Ultra Fine Circular Saw Blade

The Freud D12100X 100T Diablo Ultra Fine Circular Saw Blade is a top-rated blade that offers exceptional performance when cutting laminate flooring. With its ultra-fine teeth and high tooth count, this blade ensures clean and precise cuts with minimal chipping or splintering. The carbide teeth provide excellent durability, making it a reliable choice for both professionals and DIY enthusiasts.

DEWALT DW3128P5 Series 20 12-Inch ATB Thin Kerf Crosscutting Saw Blade

The DEWALT DW3128P5 Series 20 12-Inch ATB Thin Kerf Crosscutting Saw Blade is another popular option for laminate flooring projects. This blade features a thin kerf design, allowing for smoother cuts and reduced strain on the miter saw motor. With its high tooth count and anti-vibration design, it delivers precise and clean cuts, making it an excellent choice for both crosscuts and rip cuts.

MAKITA 723066-A-5 6-1/2-Inch 40 Tooth Circular Saw Blade

For those working with smaller miter saws or needing a blade for detailed cuts, the MAKITA 723066-A-5 6-1/2-Inch 40 Tooth Circular Saw Blade is a reliable option. This blade boasts high-quality construction and carbide teeth for durability and accuracy. It is ideal for delicate laminate flooring projects that require precise and clean cuts.

IRWIN Tools Marathon Carbide Table / Miter Circular Saw Blade

The IRWIN Tools Marathon Carbide Table / Miter Circular Saw Blade is a budget-friendly option without sacrificing performance. This blade offers carbide teeth for durability and features an anti-vibration design that minimizes potential blade wobble during operation. It delivers accurate and clean cuts, making it a great choice for DIYers and beginners working with laminate flooring.

Tips for Using a Miter Saw Blade with Laminate Flooring

While choosing the right miter saw blade is crucial, proper usage and following safety protocols are equally important for achieving the best results. Here are some essential tips for using a miter saw blade with laminate flooring:

Inspect the Blade Before Use

Before starting any cutting project, it’s essential to inspect the blade for any signs of damage or wear. Look for chipped or damaged teeth, as well as any warping or cracks. Using a compromised blade can result in unsafe cutting conditions and imperfect cuts. Replace the blade if necessary to ensure optimal performance.

Align the Blade Properly

Ensure that the miter saw blade is correctly aligned with the cutting line by adjusting the angle and depth settings on your miter saw. Incorrect alignment can lead to inaccurate cuts, chipping, or splintering. Take the time to align the blade properly to achieve clean and precise cuts consistently.

Use Appropriate Safety Gear

Whenever operating a miter saw or any power tool, be sure to wear appropriate safety gear. Safety glasses or goggles are essential for protecting your eyes from potential debris or wood fragments. Additionally, use ear protection to reduce the noise level, and consider wearing a dust mask to prevent inhalation of sawdust particles.

Adjust the Miter Saw for Optimal Performance

Ensure that your miter saw is properly adjusted for optimal performance with the chosen blade. Refer to the manufacturer’s instructions for adjusting the cutting angle and depth to achieve the desired results. Additionally, make sure the work surface is stable and secure, and always use clamps or other appropriate methods to secure the laminate flooring pieces during cutting.

Maintenance and Care

Proper maintenance and care are essential for extending the lifespan of your miter saw blade and ensuring its continued performance. Here are some maintenance tips to keep in mind:

Cleaning the Blade

Regularly clean the blade to remove any built-up pitch, resin, or debris. You can use a commercial blade cleaning solution or a mixture of warm water and dish soap. Gently scrub the blade with a soft brush, ensuring you remove all the accumulated grime. Rinse the blade thoroughly, and dry it before storing or using it again.

Storing the Blade

When not in use, it’s important to store the miter saw blade properly to protect it from damage. Consider using a blade case or a blade cover to prevent any accidental contact or exposure to other tools that may cause damage. Store the blade in a dry area away from direct sunlight to avoid corrosion or warping.

Sharpening and Replacing the Blade

Over time, the miter saw blade will inevitably become dull and require sharpening or replacement. If you notice decreased cutting performance or excessive burning during cuts, it may be time to sharpen the blade. Consult the manufacturer’s instructions or seek professional assistance for sharpening the blade. If the blade is significantly worn or damaged, it is recommended to replace it with a new one to ensure optimal performance and safety.

Common Issues and Troubleshooting

While using a miter saw blade for laminate flooring, you may encounter some common issues. Here’s a quick troubleshooting guide to help you address these problems:

Blade Binding or Stalling

If the miter saw blade gets stuck or stalls during the cutting process, it may be due to an inadequate sawdust ejection system or a dull blade. Check the blade for any potential obstructions, and if necessary, clean the ejection ports. If the blade is dull, sharpen or replace it to ensure smooth cutting.

Chipping or Splintering of Laminate

Chipping or splintering of the laminate flooring can occur if the blade is not sharp enough or if the cutting speed is too high. Ensure that the blade you’re using is sharp and well-maintained. Additionally, adjusting the cutting speed and using slower, controlled motions when cutting can help minimize chipping or splintering.

Inaccurate Cuts

Inaccurate cuts can be caused by a misaligned blade or improper adjustment of the miter saw. Check the alignment of the blade, as well as the angle and depth settings on your miter saw. Ensure that everything is properly adjusted to achieve accurate and precise cuts.

Excessive Noise or Vibration

Excessive noise or vibration can be caused by a variety of factors, including a dull blade, improper alignment, or a worn-out motor belt. If the blade is dull, sharpen or replace it. Check the alignment of the blade and make any necessary adjustments. If excessive noise or vibration persists, consult the manufacturer’s instructions or seek professional assistance to diagnose and address the issue.

FAQs about Miter Saw Blades for Laminate Flooring

To wrap up this comprehensive guide, let’s address some common frequently asked questions about miter saw blades for laminate flooring:

Can I use any saw blade for laminate flooring?

While it’s possible to use a different type of saw blade for cutting laminate flooring, it is highly recommended to use a miter saw blade specifically designed for this purpose. Miter saw blades for laminate flooring are engineered to minimize chipping, splintering, and provide clean and precise cuts.

What size blade is ideal for laminate flooring?

For laminate flooring, a blade with a diameter between 10 inches and 12 inches is considered ideal. This size allows for accurate and clean cuts, regardless of the width or length of the laminate boards.

Do I need a special type of blade for laminate flooring?

Yes, it is recommended to use a special type of blade specifically designed for laminate flooring. These blades typically have a high tooth count and special features, such as anti-vibration design and thin kerf, to ensure precise and clean cuts without chipping or splintering.

How often should I change the blade when working with laminate flooring?

The frequency of blade change largely depends on the usage and condition of the blade. If you notice decreased cutting performance, excessive burning, or visible signs of wear or damage, it’s time to sharpen or replace the blade. Regularly inspect the blade before each cutting project to ensure optimal results.

Conclusion

Choosing the right miter saw blade for laminate flooring is paramount to achieving clean, precise, and chip-free cuts. By understanding the crucial factors such as tooth count, blade diameter, and opting for carbide teeth, you can select a blade that meets your unique needs. Additionally, considering the different blade types, features, maintenance tips, and troubleshooting techniques provided in this article will enable you to make the most of your miter saw blade and ensure its longevity. With the top brands and specific blade recommendations, you can embark on your laminate flooring projects with confidence, knowing that you have the right tool for the job.