Have you ever wondered how track saws manage to stay so stable while cutting through materials? It’s all thanks to the ingenious mechanism behind their stability. This article will unravel the secrets behind the remarkable precision and control offered by track saws, shedding light on the technology that keeps them firmly in place as they glide effortlessly through even the toughest of materials. Whether you’re a woodworking enthusiast or simply curious about how these powerful tools work, join us as we explore the mechanism behind track saws’ stability and discover the secrets that make them an indispensable tool in any professional or DIYer’s arsenal.

The Mechanism Behind Track Saws Stability

Track saws are a versatile tool that have gained popularity among both amateur and professional woodworkers. One of the key features that sets track saws apart from traditional circular saws is their remarkable stability during use. In this article, we will explore the mechanisms behind the stability of track saws and understand how they ensure precise and accurate cuts.

Principles of Track Saws

To grasp the stability of track saws, it is essential to understand their basic principles of functionality. Track saws are designed to run along a guide rail or track, which serves as a constant reference point for the blade. This ensures that the cut remains straight and precise throughout the entire length of the track. By eliminating the need for freehand cutting, track saws enhance accuracy and minimize the risk of errors.

Anti-kickback Mechanisms

Preventing backward movement, also known as kickback, is a critical safety feature in track saws. Kickback can occur when the blade binds or when the material being cut closes in on the blade, causing the saw to forcefully move towards the operator. Track saws employ various anti-kickback mechanisms to mitigate this risk.

One common anti-kickback device is the riving knife, a thin, metal strip mounted behind the blade. The riving knife prevents the material from squeezing the blade and causing kickback. In addition to the traditional riving knives, some track saws feature spring-loaded riving knives that adapt to the thickness of the material, further improving safety.

This image is property of s42814.pcdn.co.

Guide Rail Design

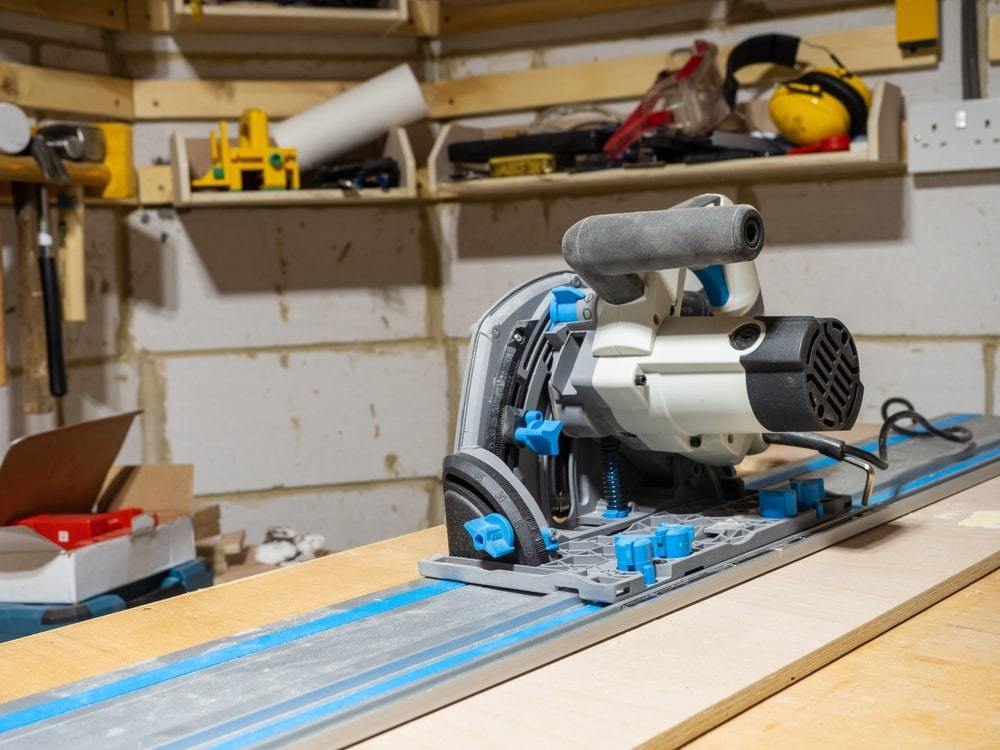

The guide rail plays a crucial role in maintaining the stability of track saws. It provides a straight and consistent cutting path, allowing for precise cuts. Guide rails are typically made from extruded aluminum or steel, ensuring durability and rigidity.

Guide rails come in different profiles, which can vary in width and depth. The profile shape helps in providing stability and accuracy while cutting. Some guide rails have a ridge in the center to improve blade alignment, while others have an edge to guide the saw foot. The attachment methods for guide rails also play a role in stability, with many track saws featuring adjustable clamps or dogs that secure the guide rail securely in place during operation.

Friction and Grip

Friction plays a vital role in the stability of track saws. The surface of the track rail should provide enough grip to prevent the saw from slipping or wandering during cuts. Different materials can be used to increase the friction between the saw and the track rail.

Some guide rails have rubberized or anti-slip coatings that enhance the grip between the saw’s base and the rail. This helps to prevent any unintentional movement or jerking of the saw during cutting. Additionally, track saw operators can use clamps and clamping systems to further enhance grip and stability.

This image is property of s42814.pcdn.co.

Saw Base and Track Connection

The design of the saw’s baseplate and its connection to the track rail play a significant role in the stability of track saws. The baseplate, often made of sturdy materials like aluminum, is designed to maintain a flat and even surface for the saw to glide smoothly along the guide rail.

The track guide attachment points on the baseplate provide a secure connection to the guide rail. These attachment points can be adjustable, allowing for precise alignment and compatibility with various track sizes. Sliding mechanisms on the baseplate ensure smooth movement along the track and prevent binding.

Precision fit and play adjustment features further contribute to stability. By fine-tuning the fit between the saw base and the guide rail, users can eliminate any play or unwanted movement, ensuring maximum stability during operation. Locking and clamping mechanisms are also commonly employed to secure the saw to the track rail, preventing any accidental disengagement.

Parallelism and Alignment

Maintaining parallelism and alignment between the saw blade and the guide rail is crucial for stability and accurate cuts. Even a slight misalignment can result in irregular and imprecise cuts. Track saws offer features that enable operators to adjust and maintain the desired parallelism and alignment.

Some track saws provide indicators or guides that assist in aligning the saw blade with the track rail. These indicators help operators achieve consistent and precise cuts. For longer cuts, mechanisms such as tightening and locking systems enable the user to secure the saw base and maintain alignment throughout the entire cut.

This image is property of cdn.thomasnet.com.

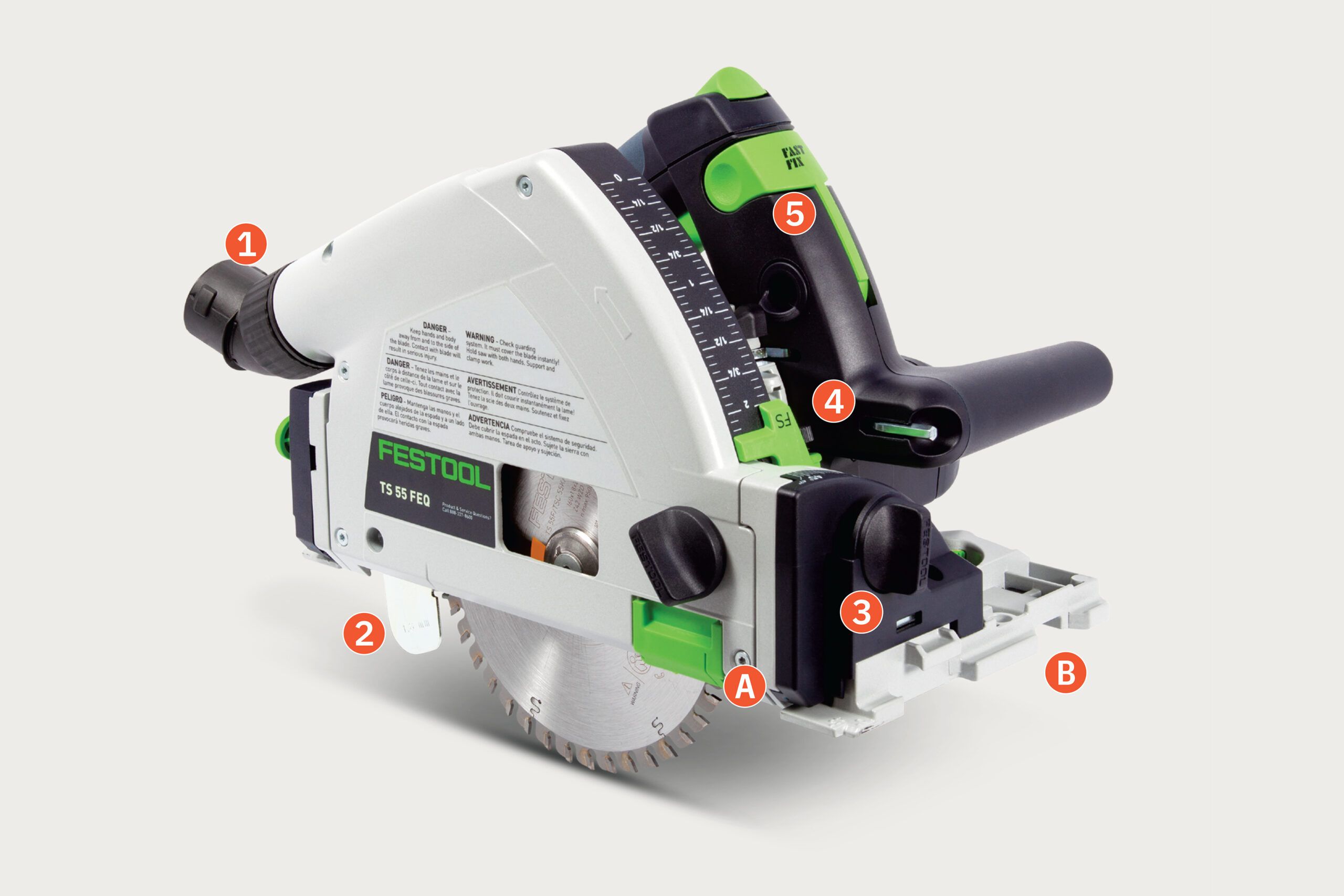

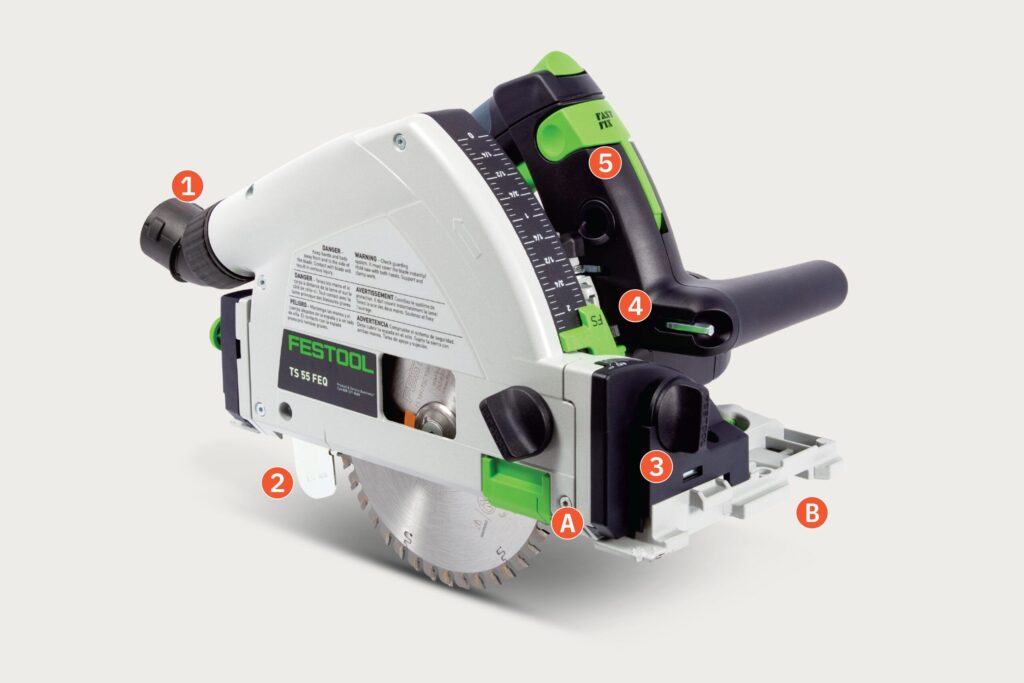

Track Saw System Components

A track saw system comprises various components that work together to ensure stability and optimal performance. The motor and drive system of a track saw are designed to deliver consistent and reliable power, enabling the saw to cut through various materials effortlessly.

The track saw blades are another crucial component that affects stability and the quality of cuts. Different blade types are available to suit specific cutting needs. From blades with different tooth counts and geometries to blades designed for specific materials, selecting the right blade for the task at hand is essential for achieving stability and desired results.

Splinter guards also contribute to stability by reducing tear-out and preventing splintering on the cut surface. These guards are typically attached to the guide rail and provide support for the material being cut, resulting in cleaner edges and improved stability.

Dust extraction systems are commonly integrated into track saws to minimize the accumulation of dust and debris. These systems help maintain a clear cutting path, improving visibility and preventing any interference with the stability of the saw.

Track connectors and other accessories complete the track saw system, ensuring compatibility and versatility. These components play a supporting role in maintaining stability and enhancing the overall functionality of the track saw.

Track Saw Blade Types

The choice of the track saw blade can significantly impact stability and the quality of the cut. A variety of blades are available, each designed for specific cutting applications and materials.

When selecting a blade, factors such as blade quality and material, teeth count, and tooth geometry should be considered. Higher quality blades tend to provide cleaner cuts and offer better stability. Different tooth counts and geometries are suitable for different materials and cutting styles, so choosing the right blade for the task is essential in achieving stability and optimal cutting performance.

This image is property of www.obsessedwoodworking.com.

Enhancements for Stability

Apart from the inherent stability features of track saws, there are various aftermarket accessories and techniques that can further enhance stability during cutting.

Additional track grips can be added to the guide rail to increase friction and grip. These grips provide extra stability and prevent unintentional movement of the saw during cuts. Adding stiffening components, such as reinforcement strips or brackets, can also improve stability by increasing the rigidity of the track rail.

Track saws can be customized and tailored to individual needs, allowing for enhancements that optimize stability. From adding anti-vibration components to installing specialized clamping systems, these modifications provide additional stability and support, ultimately improving the overall performance of the track saw.

Lastly, mastering track saw techniques can greatly contribute to stability. Proper technique, such as maintaining consistent pressure and speed, ensures smooth and controlled cuts. By familiarizing oneself with the nuances of operating a track saw, users can maximize stability and achieve excellent results.