Are you thinking about adding a table saw to your collection of tools? Before you make a decision, it’s important to consider both the advantages and disadvantages. While a table saw offers many benefits like precision and versatility, there are also drawbacks to be aware of. In this article, we will explore some of the disadvantages of a table saw, giving you a comprehensive view to help you make an informed choice. Whether you’re a seasoned woodworker or just starting out, understanding the drawbacks of this popular tool can save you time, money, and potential frustration in the long run.

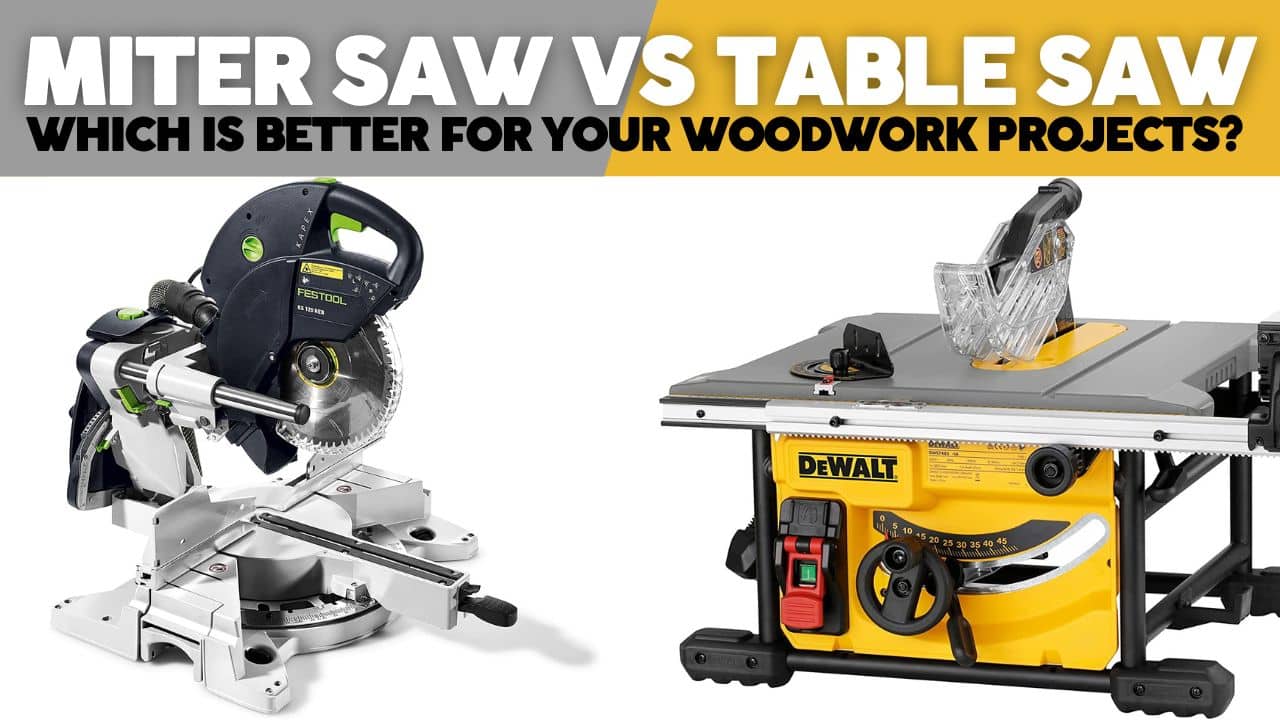

This image is property of www.nccuttingtools.com.

Safety Concerns

Lack of Blade Guard

One major safety concern with table saws is the lack of a blade guard. A blade guard is a crucial safety feature that helps protect operators from potential accidents. Without a blade guard, there is a higher risk of accidental contact with the spinning saw blade, which can result in severe cuts or amputations. It is important to always prioritize safety and use a table saw with a proper blade guard to minimize the risk of injury.

Kickback Risk

Another safety concern when using a table saw is the risk of kickback. Kickback occurs when the blade grabs the workpiece and forcefully throws it back towards the operator. This can happen if the workpiece is improperly positioned or if it encounters resistance while being cut. Kickback can happen with any table saw, but it is more prevalent with larger and more powerful saws. The force of kickback can cause serious injuries and should be avoided by using proper cutting techniques and safety measures.

Lack of Safety Features

In addition to the lack of a blade guard, some table saws may also lack other necessary safety features. For example, some models do not have a riving knife or anti-kickback pawls, which help prevent kickback incidents. These safety features are designed to minimize the risk of accidents and should be considered essential when choosing a table saw. It is crucial to invest in a table saw that is equipped with these safety features to ensure a safer working environment.

Potential for Injuries

Cuts and Amputations

Table saws have the potential to cause severe cuts and amputations if not used properly. The sharp rotating blade can easily cut through human flesh and bone, leading to life-changing injuries. It is important to always follow proper safety procedures, use push sticks or guides to keep your hands away from the blade, and wear appropriate safety gear such as goggles and gloves. Neglecting these safety measures can result in serious injuries and permanent damage.

Eye Injuries

Another potential risk when using a table saw is eye injuries. Woodworking often involves cutting, shaping, and sanding materials, creating airborne particles that can enter the eyes during the cutting process. These particles can cause irritation, scratches, or even more severe eye injuries. Wearing safety goggles or a face shield is essential to protect your eyes from flying debris and ensure your safety while operating a table saw.

Accidental Activation

Accidentally activating a table saw can also lead to injuries. Without proper safety precautions, a table saw can be easily turned on by an unsuspecting person, leading to accidents that could have been prevented. It is important to ensure that the saw is properly secured, unplugged, or locked when not in use. Additionally, keeping the key or switch mechanism in a safe place away from unauthorized personnel can further prevent accidental activation and potential injuries.

Limited Mobility

Bulky and Heavy

One disadvantage of table saws is their size and weight. Table saws are typically large, heavy machines that require a dedicated space in a workshop or garage. Their bulky nature makes it difficult to move them around, limiting their mobility and flexibility. This lack of portability can be a significant inconvenience, especially for those who need to transport or store their table saws frequently.

Requires Dedicated Space

Due to their size and design, table saws need a dedicated space to operate efficiently. This means you will need to allocate a specific area in your workshop or garage solely for the table saw. This requirement can be troublesome for individuals with limited space, as it reduces the flexibility of the workspace and may limit the ability to work on other projects simultaneously. It is crucial to consider the dedicated space needed for a table saw before investing in one.

Difficult to Transport

Transporting a table saw can be challenging due to its size and weight. Unlike handheld or portable power tools, table saws often require disassembly or use of additional equipment to move them safely. The hassle of transporting a table saw can deter individuals who frequently work at different locations or need to transport their tools to job sites. It is important to evaluate your transportation needs before investing in a table saw to ensure it aligns with your workflow.

Noise and Dust

High Noise Levels

Operating a table saw can generate significant noise levels, which can be bothersome to both the operator and those in the vicinity. The sound produced by the spinning blade and the motor can be loud and may require the use of hearing protection. While modern table saws are designed to reduce noise, it is still important to consider the potential impact on your working environment, especially if noise is a concern for yourself or others in the vicinity.

Dust Collection Issues

Table saws are notorious for creating a large amount of sawdust during use. The accumulation of dust can not only create a messy working environment but also pose health risks. Inhaling wood dust can lead to respiratory problems, especially for individuals with pre-existing conditions such as asthma or allergies. Table saws often require an efficient dust collection system to minimize the dispersion of sawdust. Without proper dust collection measures, you may need to spend additional time cleaning up after each use and take precautions to protect your health.

This image is property of www.christofix.com.

Skill and Experience Required

Difficult to Master

Operating a table saw effectively requires a certain level of skill and experience. Table saws can be intimidating for individuals new to woodworking or power tools, as they require precision and careful attention to detail. The process of measuring, adjusting, and feeding the workpiece correctly while ensuring safety can be challenging, especially for beginners. It is important to invest time in learning and practicing proper techniques to minimize the risk of errors and accidents.

Can Lead to Mistakes or Errors

Even for experienced woodworkers, mistakes or errors can occur when using a table saw. A momentary lapse in concentration or a miscalculation of measurements can lead to inaccurate cuts or unsafe working conditions. It is essential to remain focused and patient when operating a table saw, as rushing or becoming complacent can increase the likelihood of mistakes. Taking the necessary time to plan and execute each cut meticulously can help mitigate the risk of errors and ensure a safer working environment.

Expensive

High Initial Cost

Table saws can be quite expensive, especially when considering high-quality, professional-grade models. The initial cost of purchasing a table saw, along with any necessary accessories, can make it a significant investment. This expense may be prohibitive for individuals on a tight budget or those who only require a table saw for occasional use. It is essential to consider your budget and the level of woodworking you intend to undertake before making a purchase decision.

Maintenance Expenses

Apart from the initial cost, table saws also come with ongoing maintenance expenses. Regular maintenance, such as blade sharpening or replacement, lubrication, and electrical checks, is necessary to ensure the table saw operates smoothly and safely. Additionally, accessories and consumables, such as replacement blades or push sticks, may need to be purchased periodically. Budgeting for these additional costs is essential to ensure the long-term functionality and reliability of your table saw.

This image is property of images.squarespace-cdn.com.

Not Versatile

Limited to Straight Cuts

While table saws excel at making straight cuts, they are limited when it comes to creating intricate designs or curved cuts. The nature of a table saw’s design, with a fixed blade and table, makes it challenging to maneuver the workpiece in the desired manner for complex cuts. To work on intricate designs, additional tools such as a scroll saw or bandsaw may be required. It is important to assess your woodworking needs and project requirements before relying solely on a table saw for all cutting tasks.

Challenging for Intricate Designs

Even for straight cuts, table saws can pose challenges when it comes to intricate designs or precision work. The size and power of a table saw may make it difficult to achieve fine, detailed cuts or work with delicate materials. The risk of tear-out or splintering may also be higher when dealing with intricate designs. For those who frequently work on intricate projects, it may be necessary to invest in specialized tools or techniques to achieve the desired level of precision.

Time-consuming Setup

Installation and Calibration

Setting up a table saw can be time-consuming, especially for those new to woodworking or unfamiliar with the intricacies of the machine. Proper installation and calibration, including aligning the blade, fence, and miter gauge, require attention to detail and patience. Failing to set up the table saw correctly may result in inaccurate cuts, safety hazards, or decreased overall performance. It is important to dedicate sufficient time and effort to installing and calibrating the table saw for optimal results.

Adjusting and Positioning the Blade

Apart from the initial setup, each project may require adjustments to the blade height, angle, or position. These adjustments can be time-consuming, especially when working on multiple cuts or multiple angles within a single project. Switching between different cuts or angles often involves carefully readjusting the blade and the saw’s accessories, such as the fence or miter gauge, to ensure accurate and consistent results. This constant need for adjustment can add to the overall time required to complete a project.

This image is property of miro.medium.com.

Material Waste and Tear-out

Splintering and Tear-out

Table saws can sometimes cause splintering or tear-out along the edges of the workpiece, resulting in uneven and damaged cuts. This is particularly common when working with certain materials, such as plywood or fragile wood species. The tear-out can occur due to various factors, including the rotation direction of the blade, grain orientation of the workpiece, or inadequate support. Taking precautions, such as using a zero-clearance insert or using a higher quality blade with appropriate tooth geometry, can help minimize tear-out and improve the quality of cuts.

Material Wastage

Another disadvantage of table saws is the potential for material wastage. The width of the saw blade, known as the kerf, results in the loss of a small amount of material with each cut. While this wastage may seem minimal, it can add up over time, especially when working on large projects or using expensive materials. Careful consideration and planning are necessary to optimize material usage, reduce scrap, and minimize costs associated with material wastage.

Difficulty with Thin Stock

Potential for Stock Binding

Thin stock, such as narrow boards or small pieces, can be challenging to work with on a table saw. The power and force exerted by the rotating blade can cause the stock to bind between the blade and the fence, resulting in kickback or damage to the workpiece. This is particularly common when the stock is not supported adequately, is too flexible, or does not have a straight edge. Special care must be taken when cutting thin stock, ensuring proper support and using appropriate techniques to minimize the risk of stock binding and potential accidents.

Increased Risk of Injury

Working with thin stock on a table saw also increases the risk of injury. Thin stock is more difficult to handle and control, making it easier for fingers or hands to come into contact with the blade. The lack of surface area when compared to larger pieces can make it particularly challenging to maintain a safe distance from the blade. Proper use of push sticks, featherboards, or other safety accessories can help mitigate the risk, but vigilance and caution are crucial when working with thin stock on a table saw.

In conclusion, while table saws offer numerous advantages in woodworking, they also come with several disadvantages. Safety concerns, potential for injuries, limited mobility, noise, and dust, skill requirements, expense, lack of versatility, time-consuming setups, material waste, and difficulties with thin stock must all be considered when deciding to invest in a table saw. By acknowledging these disadvantages and taking appropriate safety precautions, you can minimize risks and make informed decisions about how a table saw fits into your woodworking endeavors.

This image is property of www.protoolreviews.com.