Have you ever wondered about all the things you should avoid using a table saw for? Look no further! “What Not To Use Table Saw For?” is a comprehensive guide that will enlighten you on the potential risks and dangers associated with using a table saw in unconventional ways. From cutting metal to disposing of tree limbs, this article will help you understand the boundaries and limitations of this powerful tool, ensuring your safety and the longevity of your equipment. So, before you get creative with your table saw, read on to discover what you need to avoid!

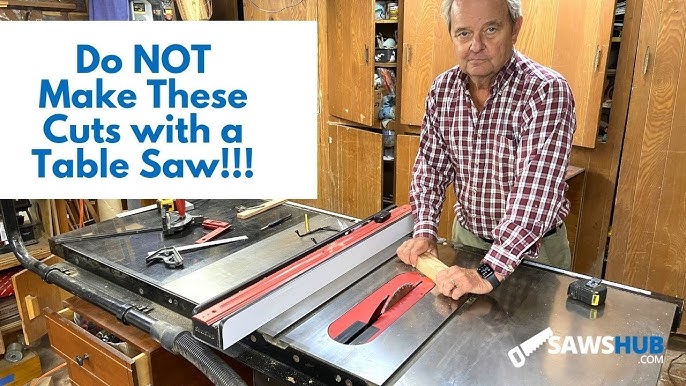

This image is property of i.ytimg.com.

Materials that should not be used with a table saw

Glass

When it comes to materials that should not be used with a table saw, glass is at the top of the list. Glass is extremely fragile and poses a high risk of shattering when exposed to the force of a table saw blade. Trying to cut glass on a table saw can result in serious injury, as shattered glass can cause lacerations and other traumatic wounds. It is best to use specialized tools and techniques specifically designed for cutting glass, such as glass cutters or diamond-tipped blades.

Concrete

Another material that should never be used with a table saw is concrete. Table saws are not designed to cut through hard materials like concrete, and attempting to do so can damage the blade and pose a safety hazard. Concrete cutting should be left to tools specifically designed for that purpose, such as concrete saws or diamond blades.

Metal

Similarly to concrete, metal is not a suitable material for a table saw. Metal requires specialized cutting tools, such as metal chop saws or angle grinders, that are equipped with the appropriate blades and safety features. Table saws are not designed to cut through metal, and attempting to do so can cause damage to the blade and result in hazardous situations.

Intricate or small cuts

Fine details

When it comes to intricate or small cuts, a table saw may not be the best tool for the job. Table saws are primarily designed for making straight cuts and are not ideal for achieving fine, detailed work. For intricate projects that require precision and attention to small details, other tools such as scroll saws or laser-guided cutting tools may be more suitable.

Small workpieces

In addition to fine details, table saws are not well-suited for cutting small workpieces. The large spinning blade of a table saw can create a dangerous situation when attempting to cut small pieces of material. These small workpieces can easily become trapped between the blade and the saw table, causing kickback or other accidents. It is safer to use a handheld power tool, such as a jigsaw or a coping saw, for cutting small workpieces.

Materials that may cause kickback

Knots in wood

Knots in wood can present a significant safety hazard when using a table saw. The dense and hard nature of knots can cause the blade to catch or bind, leading to kickback. Kickback occurs when the workpiece is thrust back towards the user at a high speed, which can result in serious injury. It is important to inspect the wood for knots and remove them or plan your cuts accordingly to avoid potential kickback incidents.

Wet or damp wood

Using wet or damp wood on a table saw can also lead to kickback. Moisture weakens the integrity of the wood and can cause it to bind against the blade, increasing the risk of kickback. Additionally, wet wood can cause the table saw’s surface and parts to become slippery, further compromising safety. It is important to ensure that the wood being used is both dry and properly seasoned before attempting to cut it on a table saw.

Materials that may damage the blade

Nails and screws

Table saw blades are not designed to cut through metal fasteners such as nails or screws. Attempting to cut wood that contains hidden or embedded nails or screws can damage the blade and cause it to become dull or even break. It is crucial to inspect the wood for any metal fasteners and remove them before cutting to protect the blade and ensure safe operation.

Rocks or hard objects

Similarly, table saw blades are not meant to come into contact with rocks or other hard objects. Rocks can damage the blade teeth and cause it to lose its cutting ability. It is essential to clear the work area from any debris, including rocks or other hard objects, to prevent damage to the blade and maintain a safe working environment.

This image is property of i.ytimg.com.

Items that may endanger safety

Body parts

One of the most important safety considerations when using a table saw is to keep your body parts well away from the cutting area. Table saw accidents can occur when fingers or hands inadvertently come into contact with the spinning blade. Always maintain a safe distance and utilize push sticks or other appropriate accessories to guide the material through the cut. Remember, safety should always be the top priority.

Loose clothing

Wearing loose clothing when operating a table saw is a safety hazard. Loose sleeves, shirts, or any other loose garments can become caught in the blade, causing severe injuries or even amputations. It is crucial to wear proper attire, such as fitted clothing without any loose ends, to reduce the risk of accidents. Additionally, it is advisable to use a push stick or other tools to manipulate the material instead of using hands directly.

Projects that require other tools

Curved cuts

Table saws are not designed for making curved cuts. If your project requires curved cuts, it is advisable to use a jigsaw, band saw, or a scroll saw. These tools have a narrower blade that allows for greater maneuverability, making them ideal for projects involving curved or intricate designs.

Angle cuts

While table saws can make straight cuts with precision, they may not have the flexibility for certain angled cuts. If your project involves making precise angled cuts, it is recommended to use tools such as miter saws or compound miter saws. These tools have built-in features and adjustable angles that make them perfect for creating angled cuts accurately and safely.

This image is property of i.ytimg.com.

Hazards associated with certain functions

Ripping narrow stock

Ripping narrow stock on a table saw can be challenging, as the material may not have enough surface area in contact with the table saw fence. This can result in instability and potential kickback. To rip narrow pieces of stock, it is best to use a band saw or a handheld circular saw with a rip guide. These tools provide better control and stability when working with narrow materials.

Crosscutting without the right setup

Crosscutting, which involves cutting wood across its grain, can be unsafe on a table saw without the appropriate setup. Without a crosscut sled or a miter gauge, it can be difficult to keep the workpiece stable and accurately guide it through the cut. It is recommended to use a miter saw or a crosscut sled on the table saw to ensure precise and safe crosscuts.

Difficult cuts that demand specialist tools

Dado cuts

Dado cuts, which involve creating a wide groove or channel in a piece of wood, require specialized tools such as a dado set. A dado set consists of multiple blades or chippers that can be adjusted to create the desired width of the groove. Table saws alone are not equipped to perform dado cuts. It is crucial to use a dado blade set along with a compatible table saw or a dedicated dado saw to achieve accurate and safe dado cuts.

Rabbet cuts

Rabbet cuts, similar to dado cuts, require specialized tools such as a rabbet bit or a rabbeting router bit. These tools are specifically designed to create recesses or grooves along the edge or face of a piece of wood. Table saws are not the ideal tool for making rabbet cuts. To perform rabbet cuts accurately and safely, it is best to use a router or a rabbet plane.

This image is property of i.shgcdn.com.

Certain projects that are not suitable

Large logs or tree trunks

Table saws are not appropriate for cutting large logs or tree trunks. The size and weight of these materials make them difficult to control and dangerous to cut on a table saw. Chainsaws or portable sawmills are more appropriate tools for dealing with large logs or tree trunks. These tools are specifically designed to handle demanding tasks and ensure safe and efficient woodcutting.

Metalworking projects

While some table saws are equipped with specialized blades for cutting non-ferrous metals, they are not the ideal tool for extensive metalworking projects. For metalworking tasks, it is advisable to use tools specifically designed for cutting and shaping metal, such as metal chop saws, angle grinders, or dedicated metal cutting bandsaws. These tools offer better control, safety, and precision when working with metal materials.

Table saw alternatives for specific tasks

Miter saw for precise angle cuts

When it comes to precise angle cuts, a miter saw is an excellent alternative to a table saw. Miter saws are built to perform accurate crosscuts and angled cuts with ease. With a miter saw, you can effortlessly create perfectly angled cuts for picture frames, molding, and other projects that require precision. Their compact size and straightforward setup make them a versatile tool for angled cutting tasks.

Circular saw for portability

If portability is a priority, a circular saw can be a suitable alternative to a table saw. Circular saws are handheld power tools that provide great mobility and can handle a wide range of cutting tasks. Though they may not offer the same level of precision as a table saw, circular saws excel at making straight cuts in various materials, including wood, plywood, and even metal. Their versatility and portability make them an ideal choice for construction sites or DIY projects on the go.

In conclusion, it is essential to know the limitations and potential hazards associated with using a table saw. Certain materials, such as glass, concrete, and metal, should never be used with a table saw, as they can pose significant safety risks and damage the blade. Intricate or small cuts, materials that may cause kickback, those that may damage the blade, and items that may endanger safety should be avoided or approached with caution. Additionally, certain projects may require other tools for specific tasks, and difficult cuts demand specialist tools. Lastly, there are table saw alternatives available, such as a miter saw or circular saw, that provide alternative options depending on the specific requirements of your project. Remember to prioritize safety and always choose the appropriate tool for the job at hand.

This image is property of sawsonskates.com.